A single-piece flow production system can increase your output while decreasing your inventory and lead time. Before you decide to implement this technology, there are several things you should consider. Measure the takt, which is how long it takes to produce an item. This allows you determine the speed at which you will need to produce an article to meet customer demand.

One piece flow is best suited to manufacturing operations that are geared towards low-variability products. It is not the right fit for all businesses. You want to make sure that you are measuring the right metrics to see if this type of process is right for your company.

A more robust and scalable control system is required if you choose to use a single-piece flow. This will help reduce waste and maximize efficiency. A one-piece item should be produced in a way that is easily scaleable to your customers' requirements. This will ensure one-piece flow doesn't have a lower production efficiency than traditional manufacturing processes.

One-piece flow involves using a production line that looks similar to a U or S shape. It reduces the amount of movement necessary to get from one step into another. It can also be assembled more efficiently.

Poka-yoke is another term associated with lean. This clever method prevents defects from being moved to the next stage. This is a great way for you to save money and improve the quality your products. The poka-yoke helps to reduce waste and improve efficiency.

When there is high demand for individual products, the one-piece flow method works well. You want to save time and money in this situation by not having to order multiple items at once. A single work item flow will reduce the cost of delay and the depreciation of your inventory. It will also reduce time that products are left in warehouses or are still in development (WIP).

You can also use a single piece flow process to reduce the costs of maintaining your inventory. This is especially true for small businesses. This allows you to cut down on the cost of inventory storage, transporting and repackaging your products. This is also a great way to reduce the amount of time you have to wait for your customers to receive your products.

The one-piece flow process also helps increase employee morale by allowing employees to work closer together. It makes it easier to identify any problems with your product. This is important because it can lead to the possibility of your customers receiving items that are defective or incomplete. This is another great way to improve your customer care.

One-piece flow production lines can be used inside or outside an assembly line. This process allows you to maximize your value stream. This allows for quicker production and better quality products. It's also a great way to cut costs and boost morale among employees.

FAQ

Why automate your warehouse?

Modern warehousing is becoming more automated. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses must adapt quickly to meet changing customer needs. In order to do this, they need to invest in technology. The benefits of automating warehouses are numerous. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety enhancements

-

Eliminates bottlenecks

-

Companies can scale up more easily

-

Increases efficiency of workers

-

It gives visibility to everything that happens inside the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

Ensures quality products are delivered on time

-

Eliminates human error

-

Assure compliance with regulations

What are my options for learning more about manufacturing

Hands-on experience is the best way to learn more about manufacturing. You can also read educational videos or take classes if this isn't possible.

What is the role of a logistics manager

A logistics manager makes sure that all goods are delivered on-time and in good condition. This is done by using his/her experience and knowledge of the company's products. He/she should make sure that enough stock is on hand to meet the demands.

What are the responsibilities of a manufacturing manager

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They must also be alert to any potential problems and take appropriate action.

They should also be able communicate with other departments, such as sales or marketing.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

Can some manufacturing processes be automated?

Yes! Yes. The Egyptians invent the wheel thousands of year ago. Today, robots assist in the assembly of lines.

There are many applications for robotics in manufacturing today. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Manufacturing could also benefit from automation in other ways. 3D printing makes it possible to produce custom products in a matter of days or weeks.

What does "warehouse" mean?

A warehouse is an area where goods are stored before being sold. It can be either an indoor or outdoor space. It could be one or both.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

Six Sigma in Manufacturing

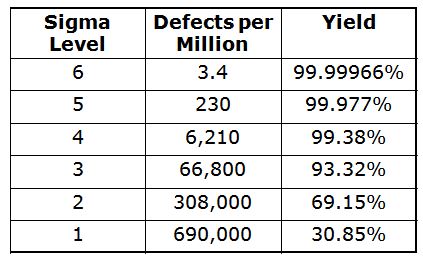

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. Many companies have adopted Six Sigma in recent years because they believe that there are no perfect products and services. Six Sigma's main objective is to reduce variations from the production average. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. This will allow you to decide if these variations are random and systematic. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. You could consider random variations if some widgets fall off the assembly lines. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

Once you've identified the problem areas you need to find solutions. That solution might involve changing the way you do things or redesigning the process altogether. You should then test the changes again after they have been implemented. If they don’t work, you’ll need to go back and rework the plan.