CEVA Logistics offers logistics services. These companies offer numerous benefits to their employees, no matter if you are looking for a job or a change in your career. Here's how you can apply to a logistics job at one of these companies. You can first search for jobs by area.

Job description

CEVA Logistics has many job openings for people with varied education and work experiences. The company's core values emphasize customer service and timely delivery. The company seeks people who are passionate about logistics, and who are willing work hard. If you have no prior experience in logistics, and if you have a positive attitude, then you will be preferred for the job.

CEVA Logistics seeks a Process/Industrial Designer to create and implement new processes. This will help improve efficiency. The ideal candidate should be energetic and self-motivated. They must also be able to work in collaboration with staff at the plant. They are responsible for designing and implementing process plans, managing projects, as well as using modeling and analytical skills. They should also be skilled in robotics and other manufacturing processes, which will increase quality and efficiency.

Education is necessary

CEVA Logistics has many career options for those who are interested in working there. These include warehouse manager and sales rep. They may also be eligible to become operations supervisors. These positions involve managing the day-today operations of CEVA Logistics, such as scheduling and inventory management, customer service, and customer support. These positions are often accompanied by a team. Candidates for these positions usually have a bachelor’s degree in logistics, supervisory and strong leadership and management skills.

Online applications are accepted from interested applicants. To apply online, candidates first need to create a profile with the company's career portal. Candidates can connect to their LinkedIn profiles to create a profile and attach their resumes. After creating their profile, they can choose the desired country or region and get in touch to a recruiter.

Salary range

The first step in applying for a CEVA Logistics job is to create an online profile through the company's Career Portal. This will allow you to connect with LinkedIn and upload your resume. You can also input details about your work experience, skills, or other pertinent information. The next step is to select a region or country where you're interested in working. Once you've completed this, you'll be provided contact information from a recruiter.

The salary structure at CEVA Logistics varies depending on the job title, experience and where you live. The Vice President of CEVA Logistics makes $166,000 a year, while an Air Break Bulk Specialist earns $24,000. However, salaries can be different in each location, depending on the economic conditions in that area.

Locations

If you're looking for a great career in logistics, consider a position with CEVA Logistics. The company has many job openings at various locations. They have different responsibilities, and different experience requirements. To apply for a job, simply type in the job title in the search box and your location. If you search for Edison, NJ jobs, you will see the listings. You must have driving experience and the ability to communicate well with clients and employees.

CEVA Logistics has many job opportunities, including supervisory posts. Supervisors oversee the day-to-day operations of the company. They manage inventory, coordinate schedules, and oversee the activities of employees. Operations supervisors typically have a team of employees reporting to them, and typically require a bachelor's degree or other related experience. Leadership and management skills are essential.

Applying online

CEVA Logistics offers a variety of jobs for people looking for work in logistics. Ceva Logistics was formed in 2006 from the merger between two Australian and Texan contract logistic companies. It has more than 9500 employees and operates in over 170 countries. Job seekers are eligible to apply for either full-time or partial-time positions.

While most jobs at CEVA require some prior experience, many positions can be filled as entry-level. Other positions require little or no experience. Customer service representative, dispatcher, and admin clerk are some of the entry-level jobs.

FAQ

What is the job of a production plan?

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. A production planner ensures that the service and product meet the client's expectations.

What are my options for learning more about manufacturing

Practical experience is the best way of learning about manufacturing. But if that is not possible you can always read books and watch educational videos.

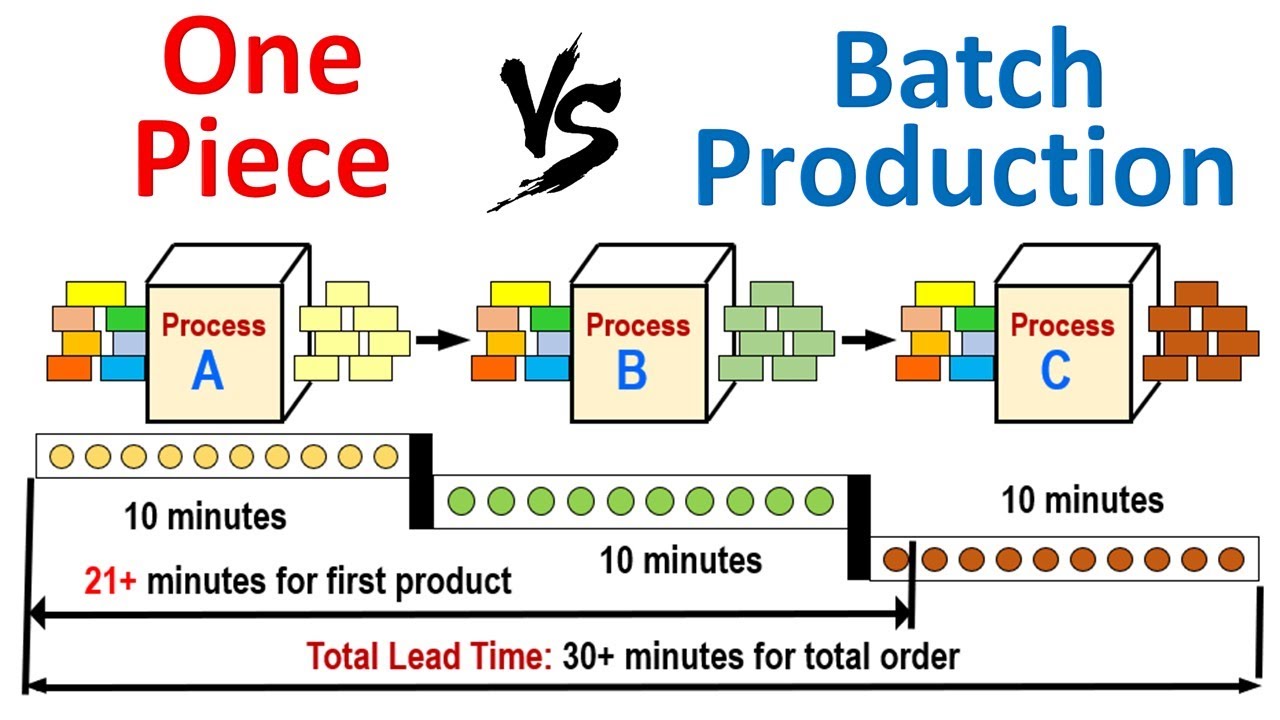

How can efficiency in manufacturing be improved?

First, we need to identify which factors are most critical in affecting production times. Next, we must find ways to improve those factors. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you identify them, look for solutions.

Why automate your warehouse?

Automation has become increasingly important in modern warehousing. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses have to be flexible to meet changing requirements. Technology investment is necessary to enable warehouses to respond quickly to changing demands. Automating warehouses is a great way to save money. These are just a few reasons to invest in automation.

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Boosts safety

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

It makes workers more efficient

-

Gives you visibility into all that is happening in your warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

This ensures that quality products are delivered promptly

-

Eliminates human error

-

It ensures compliance with regulations

How can manufacturing excess production be decreased?

It is essential to find better ways to manage inventory to reduce overproduction. This would reduce the time needed to manage inventory. This could help us free up our time for other productive tasks.

This can be done by using a Kanban system. A Kanban board is a visual display used to track work in progress. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state is assigned a different priority.

If work is moving from one stage to the other, then the current task can be completed and moved on to the next. It is possible to keep a task in the beginning stages until it gets to the end.

This allows you to keep work moving along while making sure that no work gets neglected. Managers can view the Kanban board to see how much work they have done. This information allows them to adjust their workflow based on real-time data.

Lean manufacturing is another way to manage inventory levels. Lean manufacturing emphasizes eliminating waste in all phases of production. Waste includes anything that does not add value to the product. Some common types of waste include:

-

Overproduction

-

Inventory

-

Packaging that is not necessary

-

Overstock materials

Manufacturers can reduce their costs and improve their efficiency by using these ideas.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

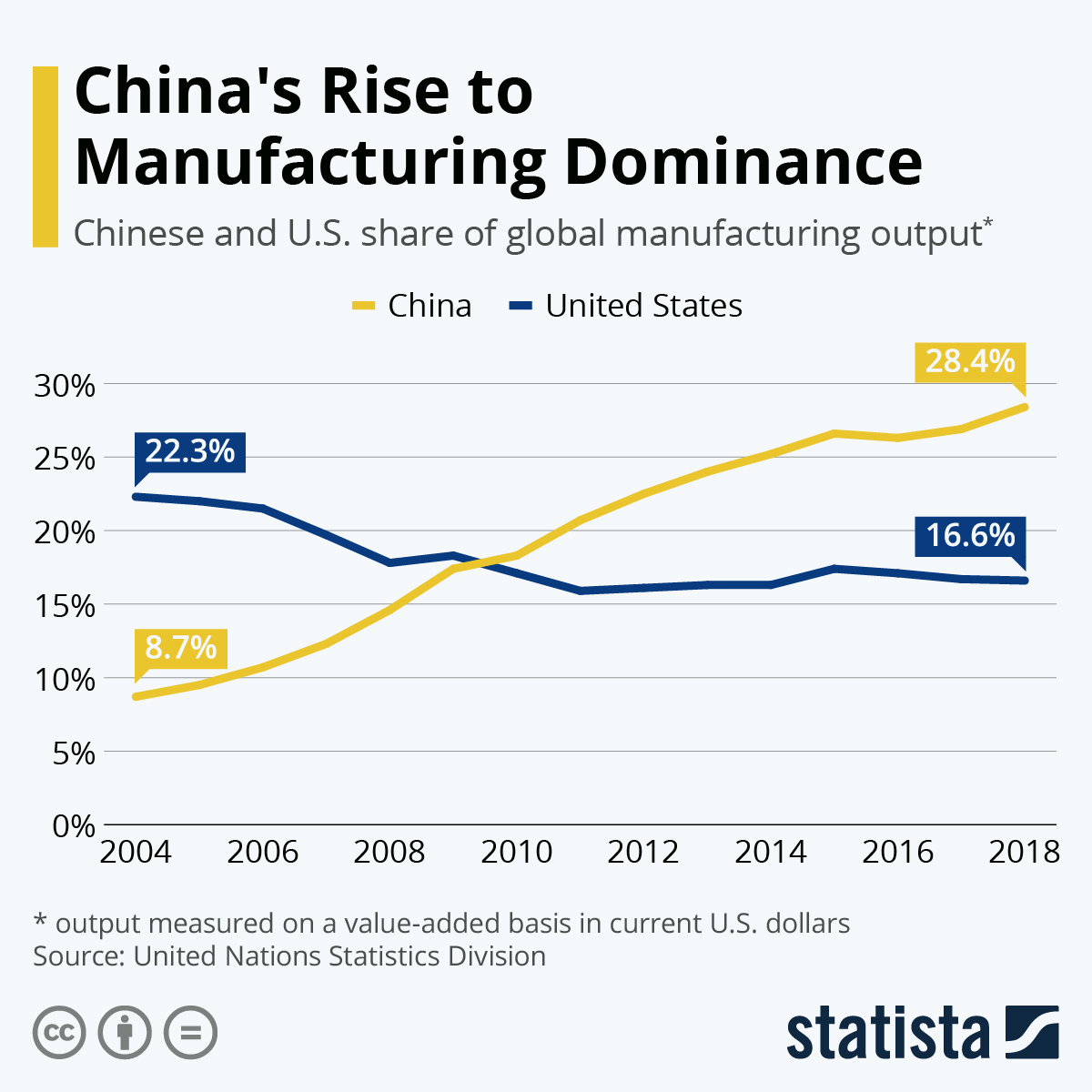

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to use the Just In-Time Production Method

Just-intime (JIT), which is a method to minimize costs and maximize efficiency in business process, is one way. This is where you have the right resources at the right time. This means you only pay what you use. Frederick Taylor, a 1900s foreman, first coined the term. He observed how workers were paid overtime if there were delays in their work. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

JIT is a way to plan ahead and make sure you don't waste any money. Also, you should look at the whole project from start-to-finish and make sure you have the resources necessary to address any issues. You'll be prepared to handle any potential problems if you know in advance. This will ensure that you don't spend more money on things that aren't necessary.

There are many JIT methods.

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will allow to track how much material has been used up. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you to predict how much you can expect to sell.

-

Project-driven: This means that you have enough money to pay for your project. When you know how much you need, you'll purchase the appropriate amount of materials.

-

Resource-based JIT is the most widespread form. You assign certain resources based off demand. For example, if there is a lot of work coming in, you will have more people assigned to them. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is similar to resource-based, except that here you're not just concerned about how many people you have but how much each person costs.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based - This is a variant of cost-based. But instead of looking at the total company cost, you focus on how much raw material you spend per year.

-

Time-based JIT is another form of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT: One of the most recent forms of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based is an inventory-based system that measures the number of items produced at any given moment. It's used when you want to maximize production while minimizing inventory.

-

Just-in-time planning (JIT): This is a combination JIT and supply-chain management. It's the process of scheduling delivery of components immediately after they are ordered. This is important as it reduces lead time and increases throughput.