A planning engineer is also called a construction planner. They are responsible for scheduling and planning the construction. They plan every aspect of the project, such as determining when it will be completed and finding the correct materials. The plan for the project's stages and schedule.

Career Plans for a Planning Engineer

Learn more about what you need to do in order to become a planning engineer. Generally, you need a bachelor's degree in engineering or a related field and several years of experience. You may also be required to obtain certification from an organization in the industry.

How to become a planning engineer

For this job, a bachelor’s degree in engineering is usually required. A strong knowledge of computer programs and the construction industry is also required. You need to be able manage a project, perform quality control, and complete projects on time and within budget.

What to Look For in a Planning Engineering

It's crucial to include your qualifications in the resume. You should also consider what attributes and skills hiring managers look for. Good organizational and communications skills, deadline meeting skills and experience on construction sites are some of the skills you should include.

What To Expect From A Planning Engineer Role

Planned engineers usually work from a computer-intensive office environment. They may also need to travel around to construction sites to ensure all work is completed properly and on schedule. They may be required to work on site during construction, which means they will need to be able to tolerate noisy and dirty conditions.

What to Expect in a Career as a Planning Engineer

As a planning engineer, you will typically start with an entry-level job and progress as your experience grows. You could become an operations or project manager. Some planning engineers decide to pursue careers as salespeople or marketers with an engineering company.

What can you expect in your professional life as a planning engineer

The average salary of a planning engineer in the United States is $150,000 per annum. However, this can vary depending on your experience and the industry and size of the company you work for. Many planning engineers earn bonuses or other incentives for meeting deadlines and completing projects.

How to Become a Planning Engineer

A planning engineer is in charge of designing and planning the entire project from start to finish. They oversee a team that includes other engineers and designers who create plans to achieve business goals. They can also help develop long-term business strategies, such identifying and investing in new technologies.

FAQ

What are the 7 Rs of logistics?

The acronym "7R's" of Logistics stands for seven principles that underpin logistics management. It was created by the International Association of Business Logisticians and published in 2004 under its "Seven Principles of Logistics Management".

The following letters form the acronym:

-

Responsible – ensure that all actions are legal and don't cause harm to anyone else.

-

Reliable - You can have confidence that you will fulfill your promises.

-

Be responsible - Use resources efficiently and avoid wasting them.

-

Realistic - Take into consideration all aspects of operations including cost-effectiveness, environmental impact, and other factors.

-

Respectful: Treat others with fairness and equity

-

Resourceful - look for opportunities to save money and increase productivity.

-

Recognizable - Provide value-added services to customers

Why is logistics important for manufacturing?

Logistics are an integral part any business. They are essential to any business's success.

Logistics plays a significant role in reducing cost and increasing efficiency.

Why automate your factory?

Modern warehouses are increasingly dependent on automation. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses should be able adapt quickly to new needs. Technology is essential for warehouses to be able to adapt quickly to changing needs. Automating warehouses has many benefits. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety increases

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

This makes workers more productive

-

Provides visibility into everything that happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

Ensures quality products are delivered on time

-

Removes human error

-

It ensures compliance with regulations

What is production planning?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document is designed to make sure everything is ready for when you're ready to shoot. It should also contain information on achieving the best results on set. This includes location information, crew details, equipment specifications, and casting lists.

The first step is to outline what you want to film. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. To narrow your options, you can search online for available models.

Once you have found the right car, you can start thinking about extras. Do you need people sitting in the front seats? Or maybe you just need someone to push the car around. You may want to change the interior's color from black or white. These questions can help you decide the right look for your car. The type of shots that you are looking for is another thing to consider. Are you going to be shooting close-ups? Or wide angles? Maybe you want to show your engine or the steering wheel. These things will help you to identify the car that you are looking for.

Once you have all the information, you are ready to create a plan. You can create a schedule that will outline when you must start and finish your shoots. The schedule will show you when to get there, what time to leave, and when to return home. It will help everyone know exactly what they have to do and when. If you need to hire extra staff, you can make sure you book them in advance. You don't want to hire someone who won't show up because he didn't know.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects may only take a couple of days, while others could last for weeks. When creating your schedule, be aware of whether you need more shots per day. Multiplying takes in the same area will result both in increased costs and a longer time. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budgeting is another important aspect of production planning. A realistic budget will help you work within your means. Remember that you can always reduce the budget later on if you run into unforeseen problems. You shouldn't underestimate the amount you'll spend. Underestimating the cost will result in less money after you have paid for other items.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

What skills do production planners need?

You must be flexible and organized to become a productive production planner. You must also be able to communicate effectively with clients and colleagues.

What is the role of a logistics manager

A logistics manager ensures that all goods are delivered on time and without damage. This is accomplished by using the experience and knowledge gained from working with company products. He/she also needs to ensure adequate stock to meet demand.

What are the responsibilities of a manufacturing manager

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They should also be aware and responsive to any company problems.

They should also be able and comfortable communicating with other departments like sales and marketing.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

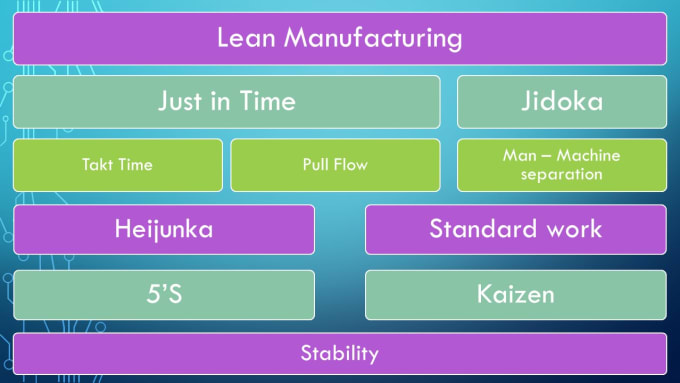

How to use 5S in Manufacturing to Increase Productivity

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation was the first to develop the 5S approach in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

This method aims to standardize production processes so that they are repeatable, measurable and predictable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. Because workers know what they can expect, this helps them perform their jobs more efficiently.

Implementing 5S involves five steps: Sort, Set in Order, Standardize Separate, Store, and Each step has a different action and leads to higher efficiency. For example, when you sort things, you make them easy to find later. Once you have placed items in an ordered fashion, you will put them together. After you have divided your inventory into groups you can store them in easy-to-reach containers. You can also label your containers to ensure everything is properly labeled.

Employees will need to be more critical about their work. Employees must be able to see why they do what they do and find a way to achieve them without having to rely on their old methods. In order to use the 5S system effectively, they must be able to learn new skills.

In addition to increasing efficiency, the 5S method also improves morale and teamwork among employees. Once they start to notice improvements, they are motivated to keep working towards their goal of increasing efficiency.